Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

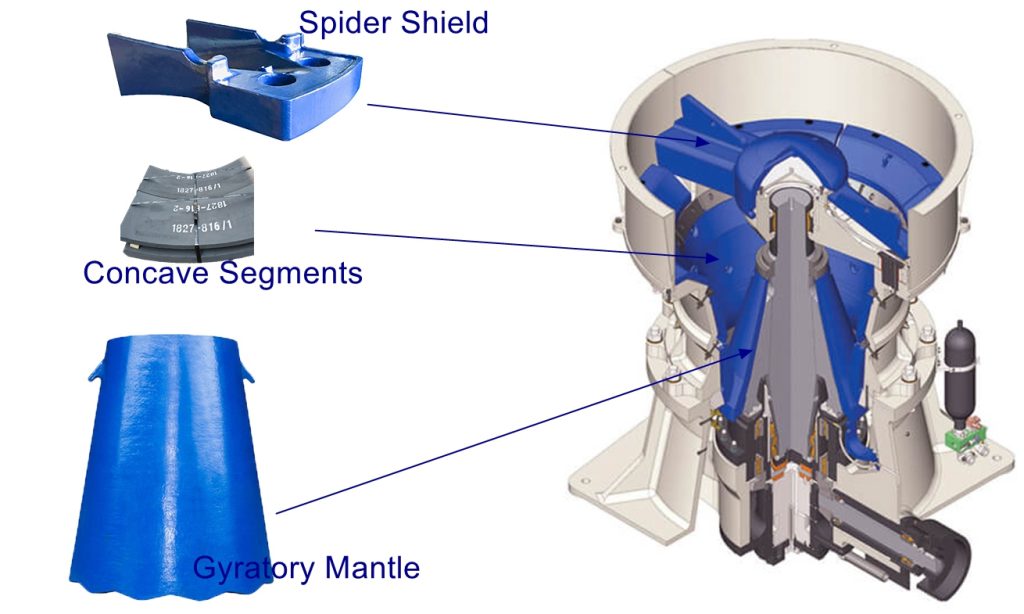

Mantle, spider liner, rim liner, segment, etc.

Machine models

42-65, 50-65, 54-75, 62-75, 60-89, 60-110.

Material

High manganese steel Mn13Cr2, Mn14Cr2, Mn18Cr2, etc

Mantle, spider liner, rim liner, segment, etc.

We offer a variety of alloys, designs and segmented bushings, depending on the application and wear rate, to achieve the best cost per ton of production.

It consists of a concave surface and a conical head; both surfaces are usually lined with manganese steel. The top of the shaft connected to the crushing cone is supported centrally by the bushing, and the bottom of the shaft is located in an eccentric bushing. The feed material is crushed between the fixed concave surface and the movable bushing. Larger rock material is crushed between the bushing and the concave surface.

Upper Intake Liners:

• Manganese alloys

• Low-alloy steel, impact resistant

Chamber Mid Liners:

• High manganese alloys

• Low-alloy steel, abrasion and impact resistant

Chamber Bottom Liners:

• Low-alloy- steel, high abrasion and impact resistant

• High-chrome special, maximum abrasion resistance

standard material is the Mn13Cr2. To further maximize performance and wear life, special designs and high-alloy options are also available.

1, Dimension accuracy and Compatibility is guaranteed;

2, Customized dimension and material service is available;

3, Reliable performance is assured by good quality;

4, Superior wear resistance property optimized for longer service life.

Superior 42-65, Superior 50-65, Superior 62-75.

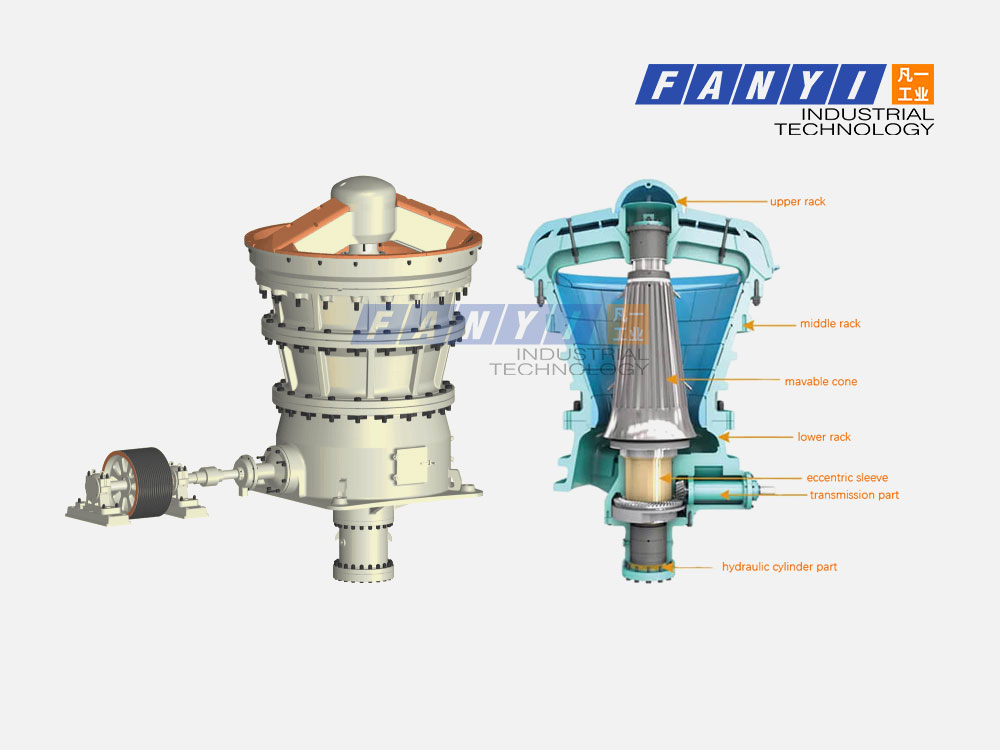

The gyratory crusher is composed of a transmission, machine base, eccentric sleeve, crushing cone, middle frame, beam, prime mover, oil cylinder, hydraulic pressure, pulley, electrical, and dry and thin oil lubrication.

The motor drives the eccentric sleeve to rotate through the pulley and the bevel gear, and when the eccentric sleeve rotates, it drives the crushing cone to swing around the center of the crusher. In this process, the materials entering the crushing cavity are continuously squeezed and bent to be crushed.

The crushed material is discharged from the bottom of the crushing chamber by its weight.