Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Steel Grinding Rods is directly from heated high carbon alloyed steel bar followed by straightening and in-line heat treatment, tailed to give uniform hardness, high resistance to both abrasion and impact and resistance to bending.

Grinding Media & Rods Available size: dia. 30mm – dia. 130 mm/length: 3.0m-6.0m & customizable

Grinding Media & Rods Grade: 60Mn, 65Mn,B2, B3,BL,BG

Steel Grinding Rods are made of a special steel which breaks up without twisting when final wear occurs. This is extremely important in maintaining full grinding capacity and eliminating the difficulty of removing wire-like, worn rods which twist and bend into an inseparable and space filling mass of interlaced wires if breaking does not occur. Rods are shipped in lengths cut to suit the length of each particular customer’s rod mill.

| Product Name | Grinding Rods |

| HS Code | 72283090 |

| Size Range | Length: 1000-8000mm, Diameter: 30-260mm |

| Specification | 40Cr, 42CrMo, 60Mn, 65Mn, 45#, B2, B3, BU, BL, BG |

| Surface Hardness | 45-60HRC |

| Impact Value | ≥12J/cm2 |

| Dropping Test | 10,000-20,000 times |

| Packaging | Bundles |

| Diameter (mm) | Length (mm) |

| 30-260 | 1000-8000 |

| Steel Specification | C | Mn | Si | Cr | S | P |

| 40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

| 42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

| 45#/ C45/1045 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | ≤0.15 | ≤0.035 | ≤0.035 |

| 65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

| B2 | 0.72-0.85 | 0.70-0.90 | 0.17-0.36 | 0.40-0.60 | ≤0.035 | ≤0.035 |

| B3 | 0.52-0.65 | 0.40-1.00 | 1.33-1.85 | 0.78-1.20 | ≤0.030 | ≤0.030 |

| BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

| BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

| 60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

| Steel Specification | Impact Value (J/cm2) | Surface Hardness (HRC) | Diameter (mm) | Length (mm) |

| 40Cr | ≥12 | 45-60 | 30-260 | 1000-8000 |

| 42CrMo | ||||

| 45#/ C45/1045 | ||||

| 65Mn | ||||

| B2 | ||||

| B3 | ||||

| BU | ||||

| BL | ||||

| 60Mn |

Steel grinding rods are high-quality steel rods that have undergone various heat treatments to maximize wear and impact resistance.

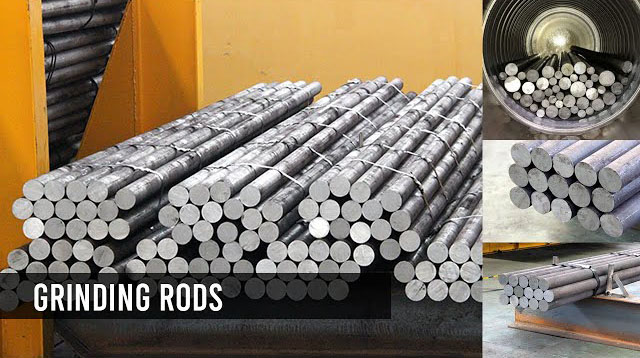

Steel Grinding Rods are used in metallurgy and mining for grinding ores such as iron, copper, and gold.

It is used for the processing of extracted minerals.

It can be used for grinding coke and friable non-metals.

It is used to grind material for glass.

It is also used to grind gravel to produce sand.

Steel mills are cheaper as they use less energy.

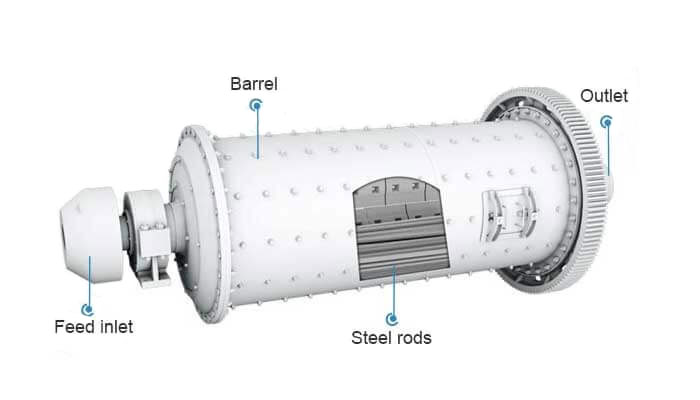

Steel rods commercially are used to construct structures like buildings, bridges, RCC roads, towers, etc. They are known to be a very strong material, Structural steel outmatches most other materials with a stress yield of 50,000 pounds per square inch. in grinding media, they are used in rod mills for three main purposes:

Rod mill can be used as fine crushing equipment to replace short-type cone crushers when crushing soft ores. It has a simple configuration, fewer costs, and low dust pollution, which can save a lot of investment in dust removal machines.

When the tungsten ore, tin ore, or other rare metal ores are selected by gravity separation or magnetic separation, a rod mill is often used to prevent over-crushing.

In the two-stage grinding process, a rod grinding machine is generally used as the first grinding equipment, which has the advantages of larger production capacity and higher efficiency

the most familiar applications of steel grinding rods are:

Steel rods are used in metallurgy and mining for grinding ores such as iron, copper, and gold.

It is used for the processing of extracted minerals.

It can be used for grinding coke and friable non-metals.

It is used to grind material for glass.

It is also used to grind gravel to produce sand.