Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Advantages of Rubber mill liners:

High wear resistance and impact resistance: The Rubber mill liners adopt a special formula and are subjected to high-pressure vulcanization treatment. The wear resistance is greatly improved and the service life is about 1.5-2 times that of the steel lining. The unique elastic buffer of the rubber itself greatly reduces the violent impact force;

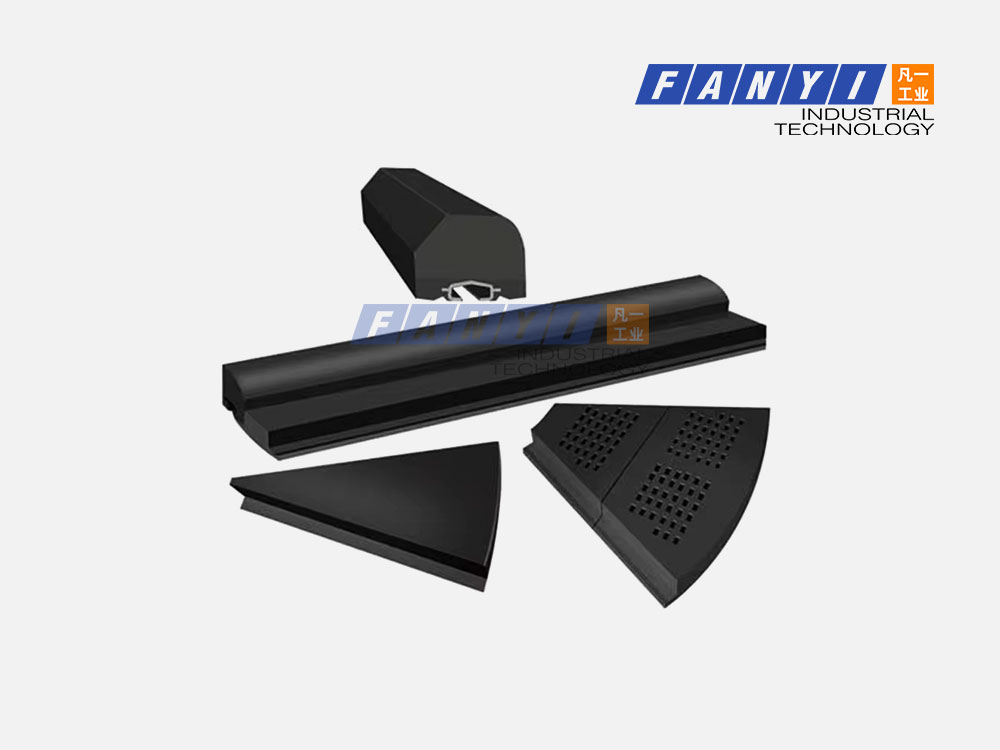

High Quality Wear-resistant rubber ball milling lining board ball mill rubber liner rubber ball mill liner plate The rubber liner is gradually replacing the manganese steel liner. It can bear strong impact of resistance. The yield of your grinding circuits is highly dependent on your mill’s rubber liner. Select right of your rubber liner supplier carefully will make sure your milling process runs at maximum capacity and availability.

Rubber liners is usually suitable for wet grinding, the temperature is not higher than 80 degrees of normal work, but for high-temperature dry grinding, strong acid and Alkali resistance, oil resistance and other special environments, need to be explained in advance by separate design formula and custom made, in addition, the storage process must be placed in indoor proper custody, it intends the rubber liners to prevent outdoor exposure under the high temperature and rain.

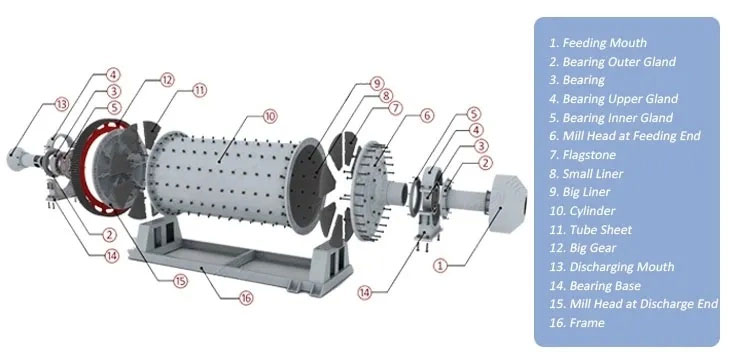

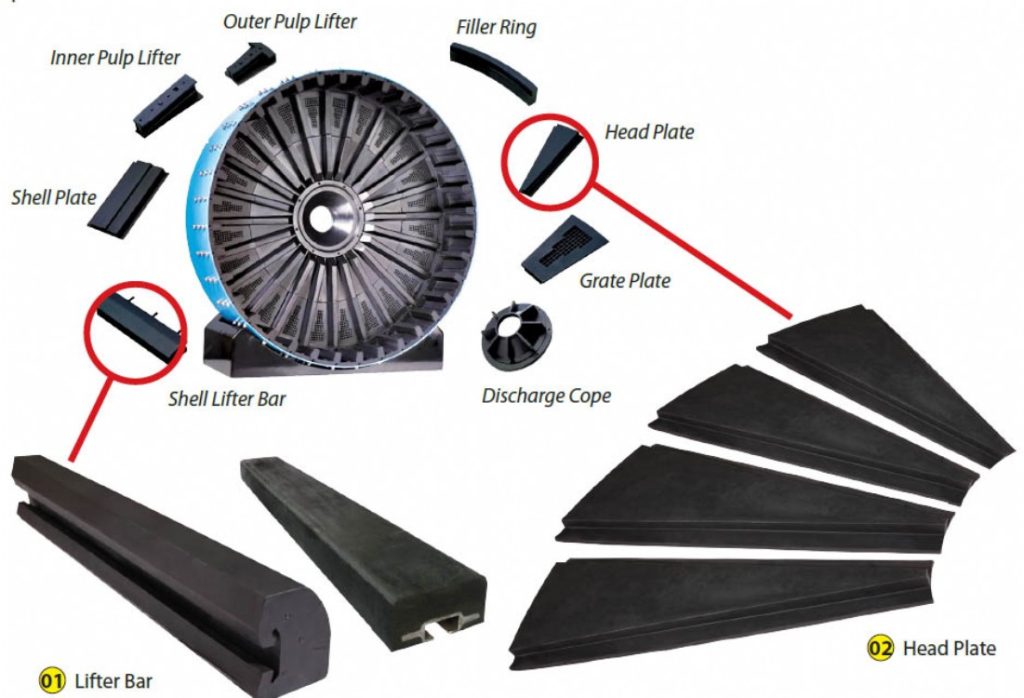

According to the purpose, the rubber liners is divided used in: AG, SAG, ball, pebble, rod & batch mills, FGD, SMD and continuous mills.

According to the shape, it is divided into overflow type, grid type and multi-bin type, which can meet the requirements of one-stage rough grinding and two-stage fine grinding.

The damp mill rubber liner consists of feed liner, shell liner, discharge grid plate liner (optional), discharge liner and fastening bolt.

The damp mill rubber liner adopts superior natural rubber and advanced manufacturing technologies, featuring high abrasion resistance, impact resistance, tear resistance, light weight, easy installation, low noise, low maintenance cost and long service life.

Cylinder part: cylinder pressure strip, cylinder lining, T-bolt

High wear resistance and impact resistance:

The rubber lining adopts a special formula and is treated with high pressure vulcanization. The wear resistance is greatly improved and the service life is about 1.5-2 times that of the manganese steel lining. The unique elastic buffer of the rubber itself greatly reduces the intense impact force;

Easy to install:

The rubber lining is light in weight and does not require special tools for installation. It is relatively convenient and greatly reduces downtime and improves the operating efficiency of the enterprise;

Save steel balls:

According to actual work calculations, compared with manganese steel linings, rubber linings can save 150,000 tons of steel balls in a mine with an annual output of 100,000 tons.

Rubber mill liners