Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

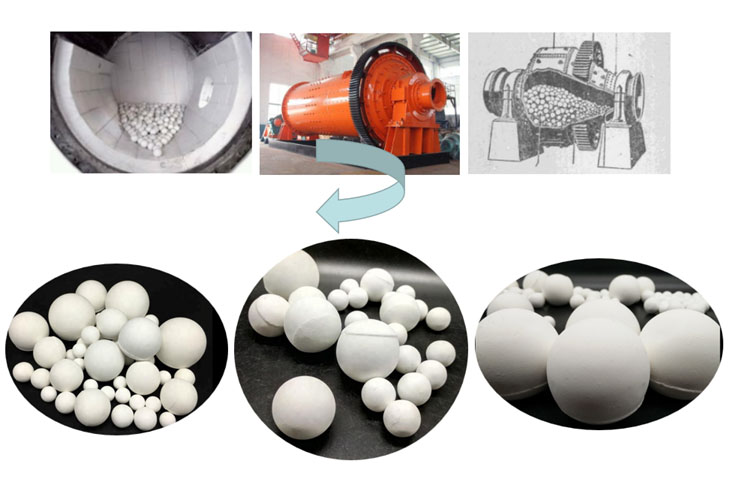

Alumina Ceramic Grinding Balls are mainly used for grinding. The grinding of ceramic balls is a kind of precision grinding system, such as ball mills, vibration grinders, etc. The grinding hardness, bulk density, corrosion resistance,wear resistance and grinding efficiency of ceramic balls are higher than ordinary stone or natural stone. Commonly used in ceramics, glass, enamel, paint, chemical and other industries.

The series Alumina grinding ball is used as grinding media for ceramic body and glaze preparation, Thanks to the excellent wear resistance and hardness, it is suitable for both wet and dry grinding in both continuous ball mill and batch ball mill

|

Performance\Product

|

GB92

|

GB92s

|

GB95

|

GB97

|

|

Al2O3(%)

|

≥92

|

≥92

|

≥95

|

≥97

|

|

Moh’s hardness

|

9

|

9

|

9

|

9

|

|

Rate of Water Absorption(%)

|

≤0.01

|

≤0.01

|

≤0.01

|

≤0.01

|

|

Bulk Density (g/cm3)

|

≥3.63

|

≥3.63

|

≥3.68

|

≥3.73

|

|

Self-Wearing Loss(%-24 hours)

|

≤0.010

|

≤0.005

|

≤0.010

|

≤0.01

|

Remark: Regular size range from Dia.10 Dia.20 Dia.30 Dia.40 Dia.45 Dia.50 Dia.60 Dia.70.

Bigger sizes like Dia.80 Dia.90 Dia.100 are available upon request.

25kg net in PP-bag or big bag of 1250 or 1000kg net. 20-25MT/20′ FCL.

Wet Grid ball mill is mainly used for mixing and grinding materials in two types: dry grinding and wet grinding. It has advantages of fineness uniformity and power saving. The machine uses different types of liner to meet different customer needs. The grinding fineness of material can be controlled by grinding time. The electro-hydraulic machine is auto-coupled and decompressed to reduce the starting current, and its structure is divided into integral type and independent type.