Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Gold Wet Pan Mill Parts, Gold Grinding Mill Parts

Based on the different structure, the types of wet pan mill is divided into single-roller type, double-roller type, three-roller type. The most often used type is a double-roller wet pan mill. As the center material is fed on the inner grinding road by two feeders.

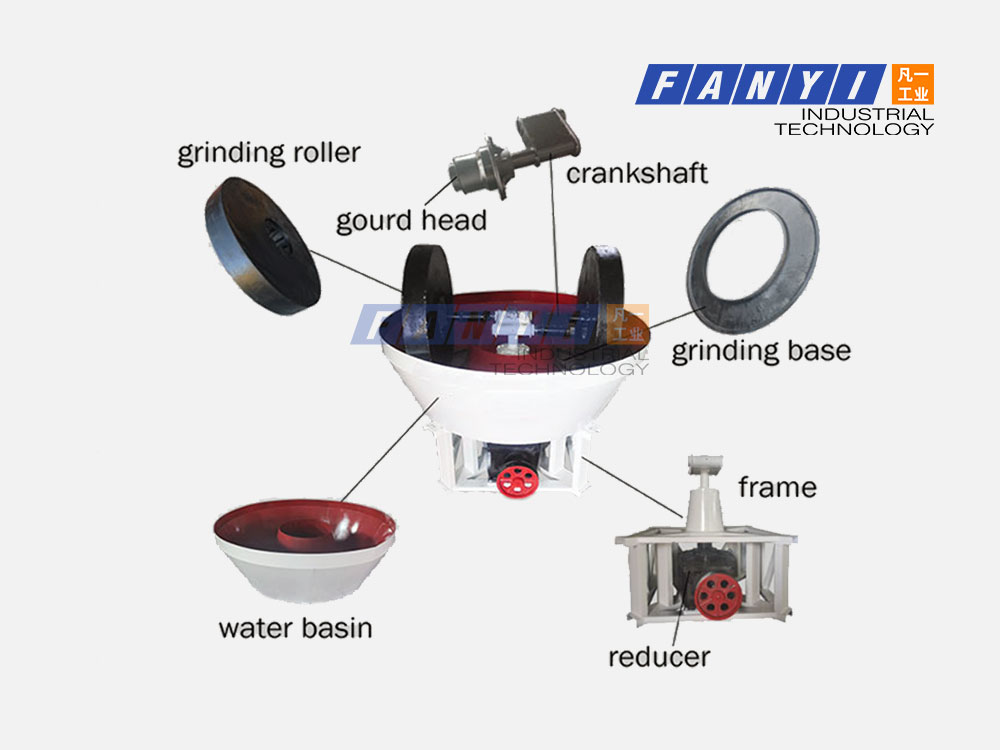

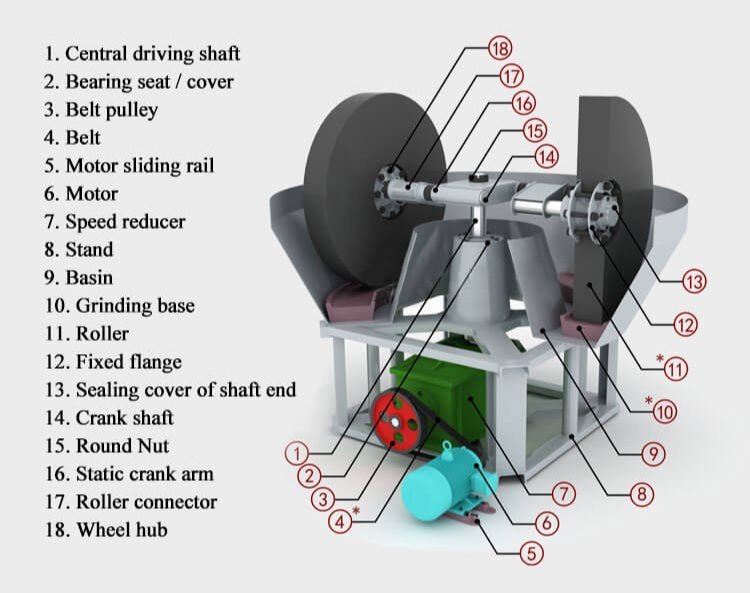

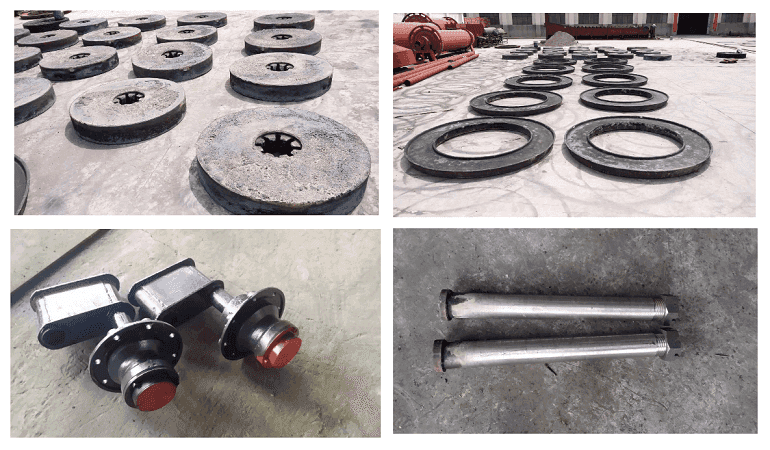

The main parts of a wet pan mill are the frame, Water basin, grinding roller, crankshaft, Grinding base, Reducer, and Motor.

Wet pan mill is also called wet grinding mill or gold grinding machine. It is the first choice of grinding equipment for small and medium milling plants in Africa and South America.

wet pan mill is particularly suitable for grinding rock gold ore, which can be ground into 100-150 mesh. Due to low cost and high production efficiency, some customers from Sudan, Egypt, and South Africa would like to purchase such gold mining machines. The most exciting thing is that you can get pure gold directly after wet grinding, thus it is quite suitable for people who want to begin a small business.

In addition, a wet pan mill is widely used in the separation of ferrous metals, non-ferrous metals as well as non-metallic minerals such as silver, lead, zinc, iron, molybdenum, copper, antimony, cement, silicate products, etc.

Based on the different structure, the types of wet pan mill is divided into single-roller type, double-roller type, three-roller type. The most often used type is a double-roller wet pan mill. As the center material is fed on the inner grinding road by two feeders.

The main parts of a wet pan mill are the frame, Water basin, grinding roller, crankshaft, Grinding base, Reducer, and Motor.

The grinding roller is more wear-resistant. And the whole machine is made of high-manganese alloy steel, which has a longer service life.