Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Product Name: Impact Crusher Blow Bars

Materials: Cr26, Cr27, Mn13Cr2 , Mn18Cr2, Mn22Cr2…

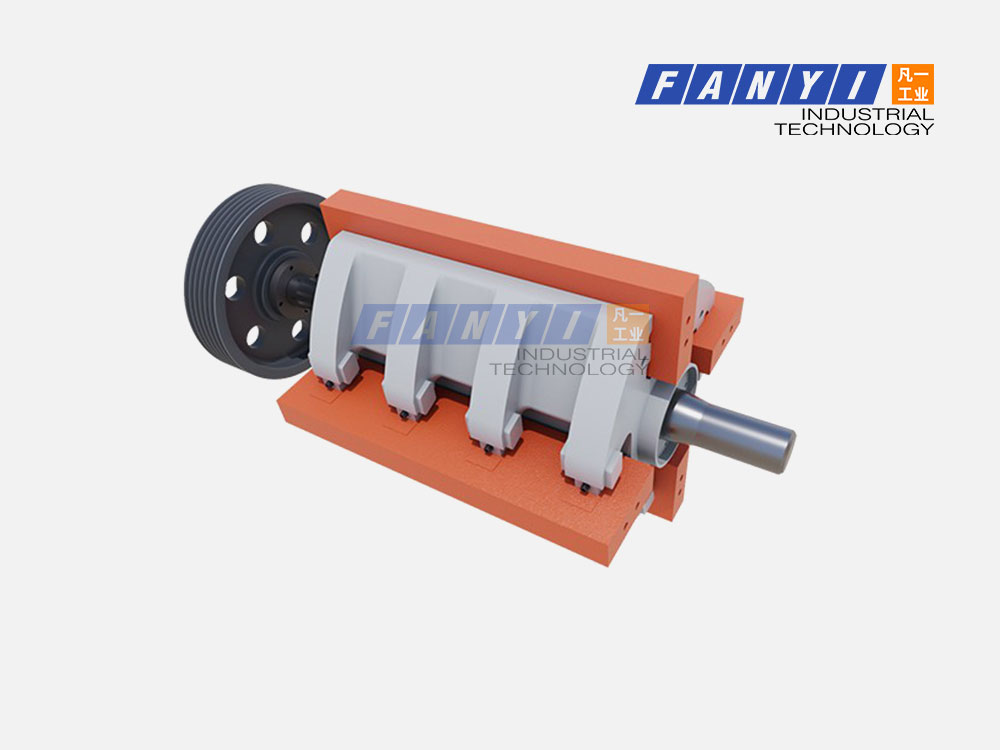

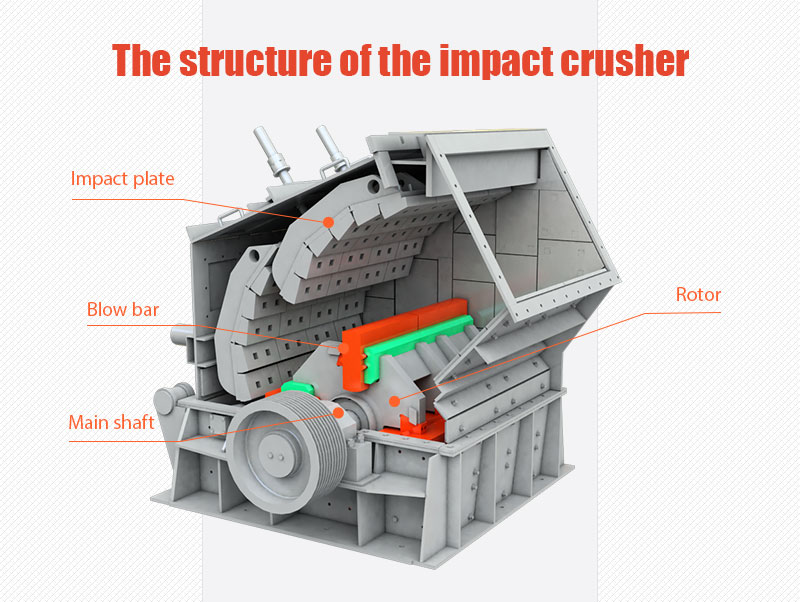

Blow bar is a key component of impact crusher.

The material of blow bar is usually selected according to the function of impact crusher.

Blow bar is a key component of impact crusher.

The material of blow bar is usually selected according to the function of impact crusher.

The blow bar of impact crusher is a thick metal plate, usually a mixture of chromium, which is forged to effectively crush materials such as ore, asphalt, concrete, limestone, etc.

| Impact Crusher | PF series | PF1007,PF1010,PF1210,PF1214,PF1315,PF1320,PF1420,PF1620 |

| NP series | NP1313,NP1415,NP1620,NP2023,NP1110,NP13,NP15,NP20 | |

| Trlo APP series | APP4354,APP5148,APP5160,APP5560,APP6384,APP8084, | |

| Trlo APS series | APS3030,APS5148,APS5160,APS4034,APS4054,APS6084 | |

| Telsmith Secondary HIS series | HS2421,HS2430,HS3036,HS3048,HS4230,HS5252,HS5263,PA6060 |

| US | Australia | British | German | South Africa | Japan | China |

| ASTM A128/A532 | AS2074 H1A/-H1B | BS3100/ BS4844 | GX 130 MnCr2 | SABS 407 Type 1 & 2 | SCMnH11 | GB/T 5680-2010 |

We Supported a wide range of alloys with different Heat treatment capabilities

Austenitic Manganese steels 14%MN, MN13CR2, MN18CR2, MN22CR2 MN13CRMO, MN18CRMO, MN22CRMO

High chromium white cast irons Chrome 15%, Chrome 25%, Chrome 30% Cr25NiMo, Cr30NiMo and Etc

Alloy steels in Various grades (SWB Germany)

High and low Carbon Steel

Ni-hard 2,3, 4

Customized Steel

| Material | C | Mn | Si | Cr | Molly | Nikker | P | S | Suit to |

| Mn14Cr2 | 1.0-1.3 | Mn:11-14 | 0.3-0.6 | 1.7-2.4 | — | — | ≤0.05 | ≤0.03 | Jaw Plate, Side Plate, Mill Liner |

| Mn14Mo1 | 1.0-1.3 | Mn:11-14 | 0.3-0.6 | — | 0.8-1.2 | —- | ≤0.05 | ≤0.03 | Shredder Hammer, Track Shoe |

| Mn18Cr2 | 1.1-1.4 | Mn:17-20 | 0.3-0.6 | 1.7-2.4 | — | —- | ≤0.05 | ≤0.03 | Jaw Plate, Bowl Liner, Mantle |

| Mn18Cr2Mo0.6 | 1.1-1.4 | Mn:17-20 | 0.3-0.6 | 1.7-2.4 | 0.6-0.8 | — | ≤0.05 | ≤0.03 | Hard Abrasive Rock Crushing |

| Mn22Cr2Mo | 1.1-1.4 | Mn:20-24 | 0.3-0.6 | 1.7-2.4 | —- | —- | ≤0.05 | ≤0.03 | Heavy Duty Concave, Mantle |

| KMTBCR15 | 2.8-3.2 | Mn:0.6-0.8 | 0.6-0.8 | 14.5-15.5 | 0.2-0.3 | 0.2-0.3 | ≤0.06 | ≤0.06 | Paddle Arm, Tip And Mixer Liner |

| KMTBCR27 | 2.8-3.3 | Mn:0.6-0.8 | 0.6-0.8 | 26.5-28 | 0.3-0.5 | 0.3-0.5 | ≤0.06 | ≤0.06 | Blow Bar, Paddle tip, VSI Parts, Anvil |

| KMTBCR30 | 2.8-3.3 | Mn:0.6-0.8 | 0.6-0.8 | 28.5-30 | 0.3-0.5 | 0.3-0.5 | ≤0.06 | ≤0.06 | Blow Bar, Paddle Tip, VSI Parts |

| Cr27Ni2Mo1 | 2.8-3.3 | Mn:0.6-0.8 | 0.6-0.8 | 26.5-28 | 0.8-1.2 | 1.5-2.0 | ≤0.06 | ≤0.06 | Heavy Duty Blow Bars |

| Ni-Hard | 2.8-3.2 | 0.2-0.8 | 1.5-2.2 | 8.0-10.0 | 0.3-0.5 | 4.0-5.5 | ≤0.06 | ≤0.06 | Mill Liner, Augers, Paddle Tip |

| Martensite Alloy Steel | 0.3-0.6 | 0.8-1.5 | ≤1.2 | 1.8-2.3 | 0.2-1 | 0.5-0.8 | ≤0.06 | ≤0.06 | Blow Bar, Mill Liner etc |

| Carbon Steel | 0.08-0.25 | 0.3-0.6 | 0.15-0.35 | —– | —- | —- | ≤0.045 | ≤0.045 | Torch Ring, Shell, Bowl, Cone |

Widely used in the Mining Industry, Quarrying & Aggregate, metallurgical and Recycling industry, construction Plants, heavy engineering Industries, chemical industry, and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone, quartz, Basalt, Granite, Building Waste, Metal Scrap and so on.