Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

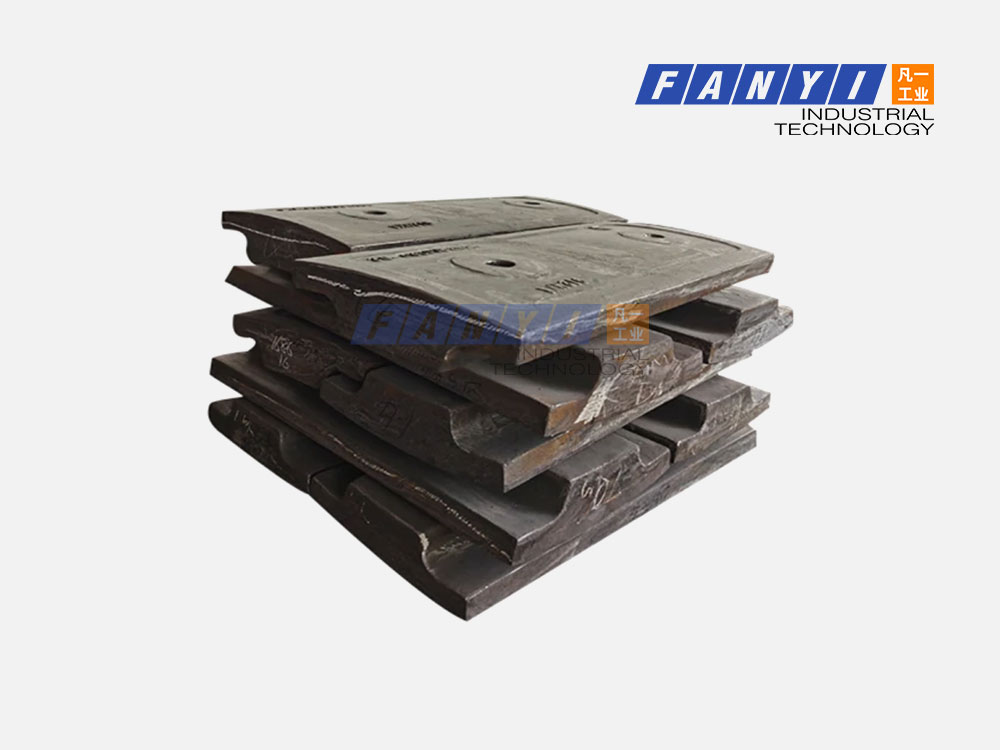

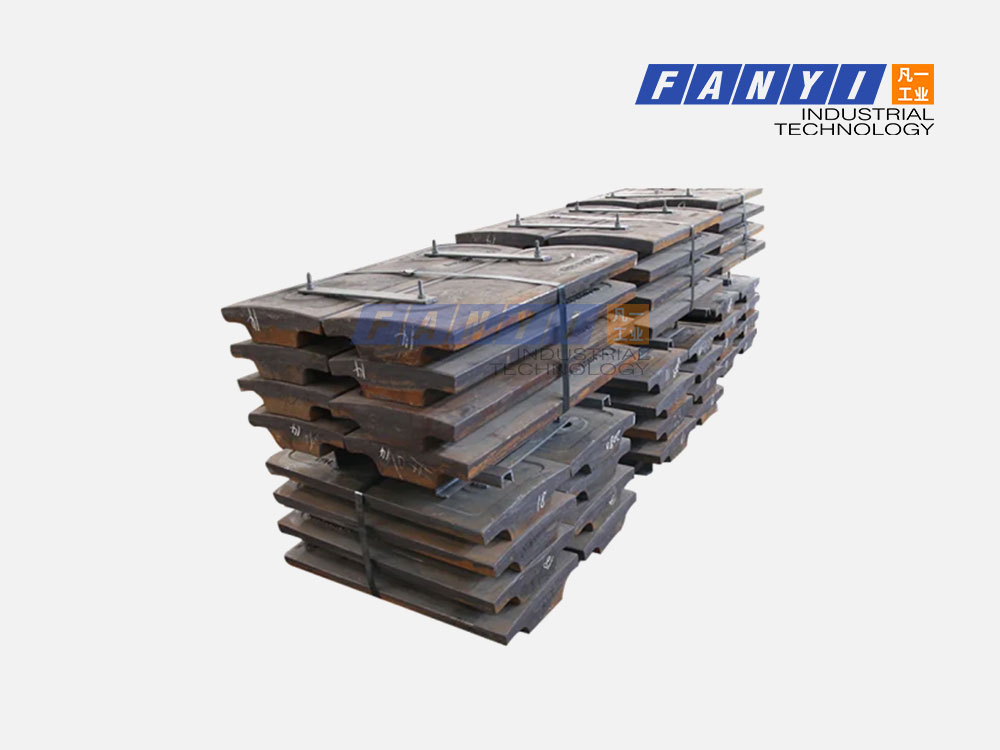

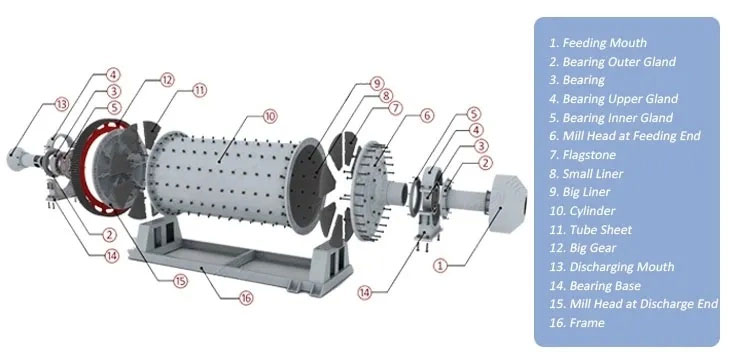

The Metallic mill liners are used to protect the shell in order to avoid the impact and abrasion from the materials and grinding medium. Different types of mill liners can be used to adjust the movement of materials. Grinding Mill Parts

The mill liners are used to protect the shell in order to avoid the impact and abrasion from the materials and grinding medium. Different types of mill liners can be used to adjust the movement of materials.

Metallic mill linings are the traditional linings familiar to most mines. Improve uptime and maximize your grinding performance by using Metso’s high-quality steel mill linings with an optimized design.

I can offer solutions for all kinds of mills, such as cement mills, mine mills, ball mills, rod mills, AG mills, SAG mills, etc.

Grinding wear parts are subjected to different combinations of impact and abrasion, as they are used in SAG/AG, ball or rod mills. Our wear parts are manufactured to the highest standards of quality, traceability and delivery, ensuring high levels of reliability for our customers. Also, our wear parts add value to customers’ processes through customized designs The use of internationally recognized advanced specialized software simulation mill liners for lining structure, size to optimize the design.

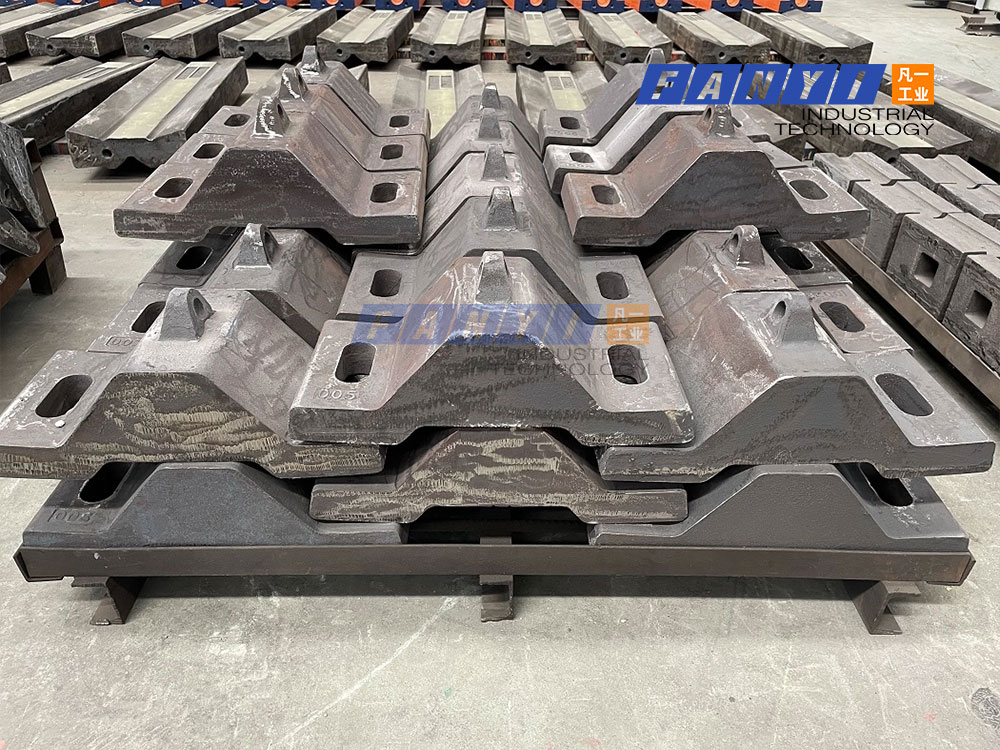

Barrel and cap are made of wear-resistant liner material chrome molybdenum alloy steel, the use of convex liner, improve service life and grinding effect.

Liner with a flat head bolts, supporting self-locking nut and ferrule. Coupling bolts with special seals to prevent leakage of plasma.

Quantity bolted liner wealthy amount of 5%.

Cover and cylinder liner wear-resistant rubber padding junction strip, which is fixed by the close of the liner.

Rubber gasket between the cylinder liner and a thickness of 6mm, noise can be reduced.

SAG/AG Mill Liners:

Integrated and/or plate and lifter designs for head and shell liners

Grates

Pulp lifters

Filler rings

Ball Mill Liners:

Single wave liners

Modified single wave liners

Double wave liners

Shell liners

Feed head liners

Discharge end liners

Rod Mill Liners:

Shell liners

Head liners

“Wedge” shell liners

Specification for Steel Castings for Grinding Mill

a. ASTM A609

b. ASTM A609 S1

For ASTM A 216 WCA Steel (modified):

| Chemical composition | Maximum percent allowable |

| Carbon | 0.24% ( 0.28%) (0.28% for head and trunnion) |

| Manganese | 0.90% |

| Silicon | 0.30-0.45% |

| Sulfur | 0.025% |

| Phosphorus | 0.025% |

| Nickel | 0.25% |

| Chromium | 0.20% |

| Molybdenum | 0.15% |

| Cooper | 0.20% |

| Vanadium | 0.03% |